Products

contact

Tongsai Industry (Shanghai) Co., Ltd

Mobile:18116302211

Contacts:William Yin

Tel:021-57883609

Fax:021-57883607

E-mail: tongsai1771@163.com canlong1771@163.com

Address:291 Zhangtang Road, Songjiang District, Shanghai

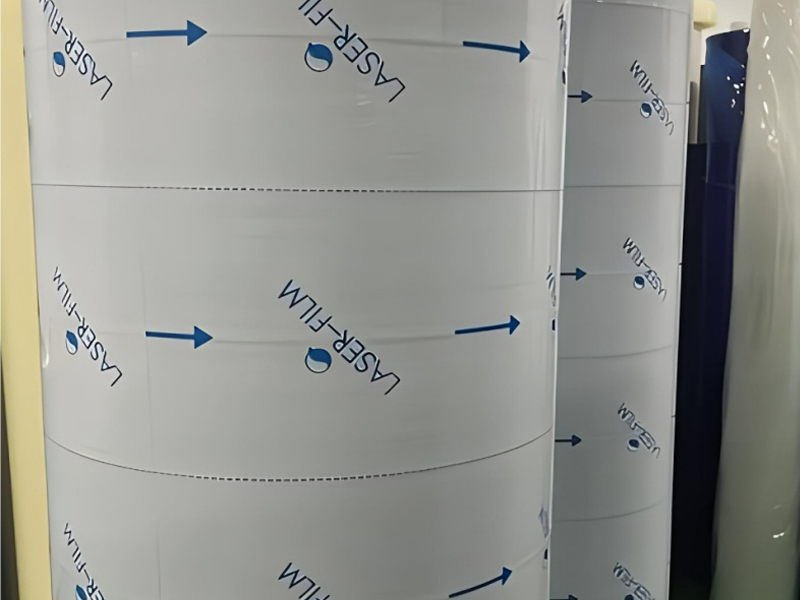

Laser cutting protective film

Product Name:Laser cutting protective film

Product Description:

Due to its special performance, it is specifically designed for the protection of laser engraving mirror stainless steel plate processing. Used for laser engraving mirror stainless steel plates to protect their surface from damage. During use, there is high temperature and strong airflow. After use, it needs to be able to peel off smoothly under the pressure generated by stacking without contaminating the protected surface. It can achieve no warping, no deformation, and a neat cross-section.

Product Usage:

Suitable for laser engraving surface protection of mirror stainless steel plate products. Pressure sensitive adhesive, resistant to high temperatures below 200 degrees Celsius without leaving any residue.

Product performance:

The protective film has multiple advantages that differ from other products: it can be used to cut steel plates with film protection in one go using a laser; During laser cutting, the protective film will not peel off or bubble; After laser cutting, there will be no black spots left on the stainless steel; The protective effect outdoors can last up to six months; The protective film can be easily removed as a whole without resistance or tearing; There are special printed characters on the protective film, indicating that the steel plate with the protective film can be directly laser cut, and the rolling and brushing directions of the steel plate are also printed.

It can reduce the cutting time of laser on steel plates and protect the surface integrity of the cut parts during mechanical processing (bending, punching, stamping, forming, etc.). The steel plate with protective film can be transported using automated machinery, and during operation, two steel plates will not be lifted at once due to adsorption.

...