Your current location:Home > Products

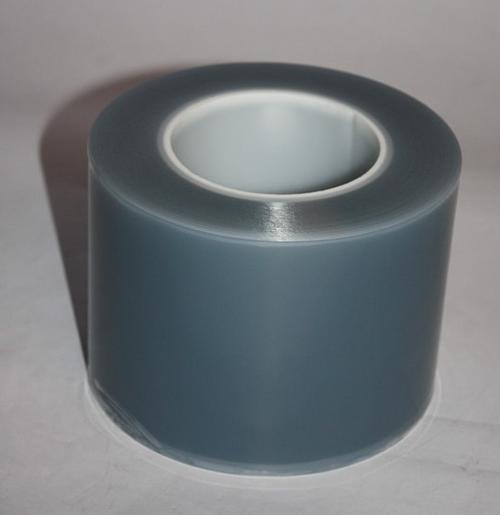

Anti static protective film

Product name: PE、PET anti-static protective film (anti-static protective film)

Total thickness: 0.05mm (supports customized thickness)

Anti static value: 10 ^ 6-10 ^ 9

Adhesive force: 3g-30g (supports customization)

Dimensions: 4mm wide, 50mm, 1200mm long, 200m, 500m (supports customized width and length)

Performance and purpose:

1. Anti static PE protective film is mainly used for the protection of glass and plastic surfaces, which not only does not leave adhesive residue, but also controls the stripping voltage during the stripping period, so that the protective film will not produce a large voltage to breakdown the pasted object during stripping.

The period is mainly divided into two types: single-sided (adhesive side) anti-static and double-sided (adhesive side, reverse side) anti-static.

The principle of anti-static with adhesive surface is to add an anti-static agent to the adhesive and then apply it to make it have an anti-static effect.

There are two ways to resist static electricity on the reverse side: one is to apply a layer of anti-static coating on the PET film, and the other is to add a coating, which can easily damage the coating during storage and transportation, and weaken the anti-static effect. This is why the storage period of anti-static protective film is shorter than that of ordinary protective film, and its advantage is low cost.

The latter method of adding anti-static agents has the disadvantage of high cost, but its relatively long shelf life makes many users choose to use this protective film for shipping protection.

An anti-static protective film is a type of anti-static agent added to the substrate or adhesive of the protective film. This anti-static agent can effectively absorb the "water" on the surface of the product and in the air, and the water can be neutralized with static electricity. Thus achieving the effect of anti-static. This is relatively simple. Most protective films are made of PP/PE raw materials. Before blowing, an anti-static agent is added and mixed evenly through screw plasticization, and then blown. After the product is produced, due to the distribution of anti-static agents inside the resin, and the fact that the anti-static agent is a low molecular weight surfactant with hydrophilic and hygroscopic properties, it is easy to migrate from the inside of the resin to the surface of the product, which is hydrophilic (absorbing air moisture), forming a layer of water molecules, thus achieving the effect of electrostatic discharge.

Scope of use:

1. Plasma TV screen protector film.

2. Laptop screen protector sticker.

3. LCD screen protector film protective sticker.

4. Game console LCD screen protector film protective sticker.

5. Apply electrostatic protective film and electrostatic adhesive protective film.

6. Electronic dictionary LCD protective film.

7. Screen protector for mobile phones, digital cameras, and cameras.

8. Car DVD display screen GPS LCD protective film.

9. Surface hardening treatment of PET polyester film (thin film switch material)

...